Shape Memory Alloy (SMA) Damping for Smart Miniature Systems

Shape Memory Alloy (SMA) Damping for Smart Miniature Systems

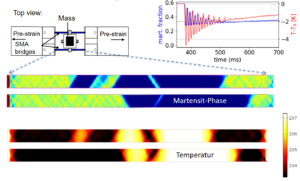

In many applications, uncontrolled mechanical vibrations are a potential source of noise and damage. On the large scale, Shape Memory Alloy (SMA) dampers are used in massive structures like buildings and bridges to reduce the impact of seismic loads. In the past couple of decades, there is a strong drive towards miniaturization with integration of many sensors/actuators at small footprint. Vibration damping and control for small and micro-scale systems is challenging, as most damper concepts used for large structures cannot easily be downscaled. In this joint project between FAU and KIT (Karlsruhe), miniature dampers and vibration control using SMA foil (or thin film) based devices are developed. This goal is targeted by combining material characterization, fabrication and device simulation. As applications, miniature robotics and smartphone camera stabilization against hand movements are chosen. By using SMA foils, design flexibility and miniaturizability are achieved.

SMAs are functional materials capable of undergoing large reversible deformation through which large amounts of mechanical energy are dissipated. This unique behaviour is attributed to the underlying phase transformation of the material between austenite and martensite phases. Unlike other velocity dependent damper concepts, the energy dissipation in SMA is heavily dependent on the loading strain. Depending on the operating temperature, SMAs exhibit two types of behaviours called pseudoelasticity or one-way shape memory effect. The material shows pseudoelasticity when operated above austenite finish temperature (Af) and one-way shape memory effect below martensite finish temperature (Mf). In pseudoelastic SMA, the strain recovery occurs upon unloading. In a mechanical loading cycle, large amount of energy is dissipated by material hysteresis which is used to develop passive dampers. In one-way SMA, the strain recovery occurs when the material is heated above Af. This principle is used to develop active dampers and actuators for vibration control.

Funding

Project: Dämpfung von intelligenten miniaturisierten Systemen mit Formgedächtnislegierungen

(Third Party Funds Single)

Project leader: Frank Wendler

Start date: 1 February 2018

End date: 30 September 2019

Funding source: DFG-Einzelförderung / Sachbeihilfe (EIN-SBH)